RO Cleaning chemical

RO membrane chemicals should be cleaned with high and low pH cleaning chemicals. The high pH cleaning should always be performed first to remove biological or organic foulants, both of which contain carboxylic functional groups. These weak acids gain an anionic charge at high pH, allowing them to disperse. High pH cleaning chemicals chelate the calcium that bridges foulants and biofilms to each other and to the membrane surface. Commodities such as NaOH are only mildly effective because of their inability to remove the calcium bridging.

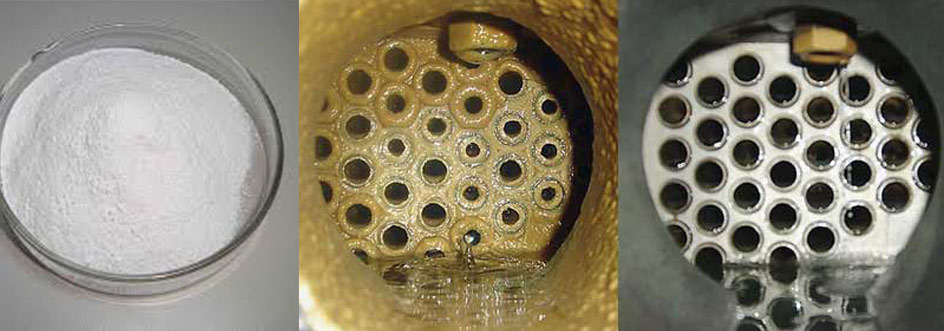

In normal operation, the membrane in reverse osmosis elements can become fouled by suspended solids, microorganisms, and mineral scale. These deposits build up during operation and cause loss in water output or salt rejection, or both. Regular cleaning of the membrane elements minimizes the loss of performance and extends membrane life.

When performing a cleaning, the first 20% of the cleaning solution is flushed through the membranes directly to drain, instead of circulating. This will prevent contamination of the cleaning solution with loose foulants and large suspended solids.

The remaining solution is then circulated through the system while carefully monitoring the pressure differential (dP). dP should not exceed 10 PSI (0.69 bar) per membrane element. Every 30 – 60 minutes, the circulation can be stopped to allow the membranes to “soak” for about 30 – 60 minutes. Circulation should then be started again to flush off the disintegrated foulant and to bring fresh cleaning chemical to the membrane surface. pH should be checked every 15 minutes during circulation. If the pH of the cleaning solution has changed, more cleaning chemical should be added to adjust the pH back to the target range.

Soaking and circulating can be repeated alternately until cleaning is complete. Cleaning is determined to be complete when the pH stabilizes.